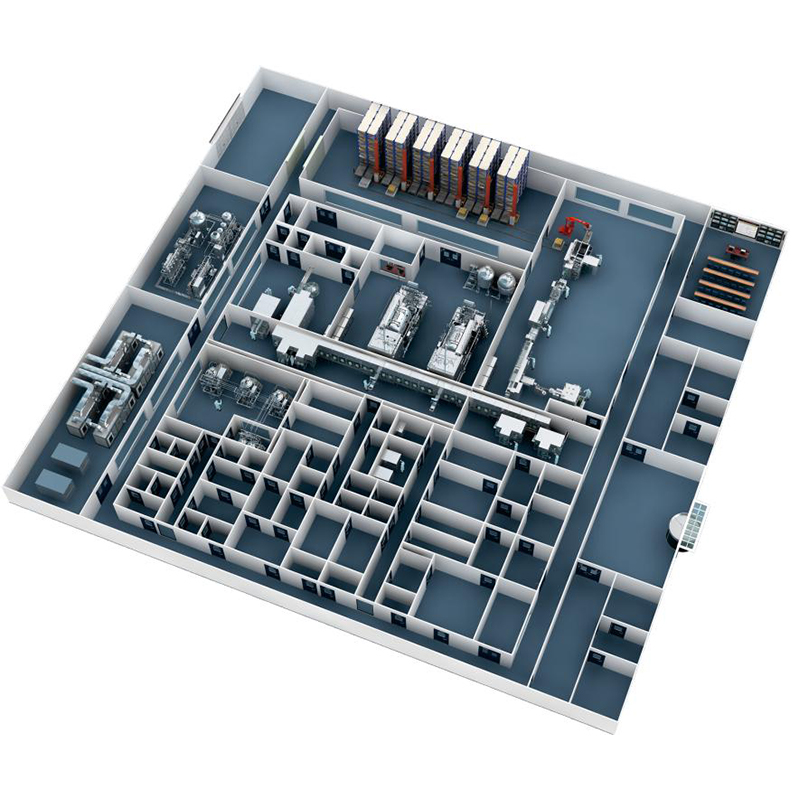

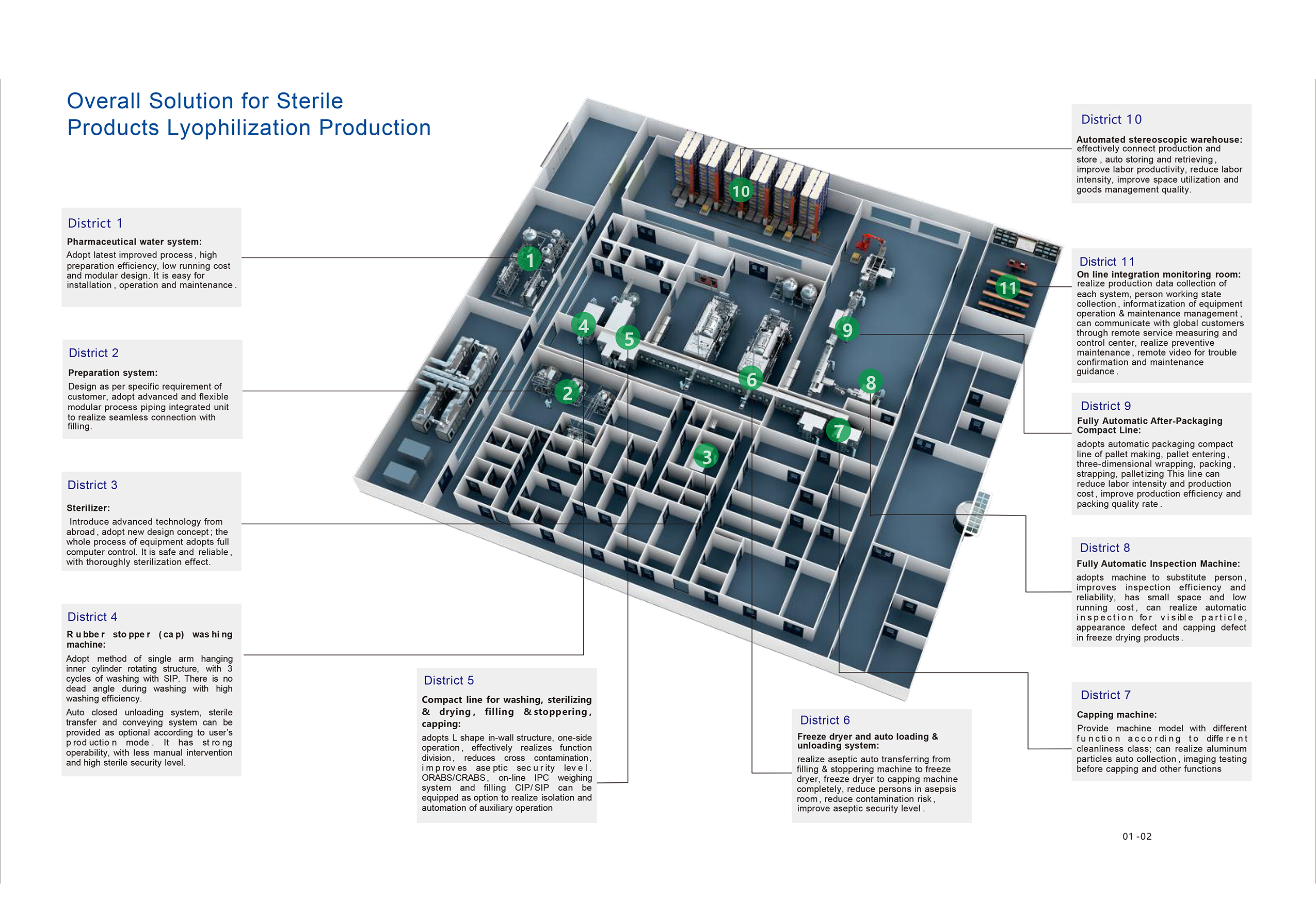

District 1

Pharmaceutical water system:

Adopt latest improved process ,high preparation efficiency, low running cost and modular design. It is easy for installation , operation and maintenance .

District 2

Preparation system:

Design as perspecific requirement of customer, adopt advanced and flexible modular process piping integrated unit to realize seamless connection with filling.

District 3

Sterilizer:

Introduce advanced technology from abroad , adopt new design concept ; the whole process of equipment adopts full computer control. It is safe and reliable,with thoroughly sterilization effect.

District 4

Rubber stopper ( кепка) was hing machine:

Adopt method of single arm hanging inner cylinder rotating structure, с 3 cycles of washing with SIP. There is no dead angle during washing with high washing efficiency.Auto closed unloading system, sterile transfer and conveying system can be provided as optional according to user’s production mode .It has strong operability, with less manual intervention and high sterile security level.

District 5

Compact line для washing, sterilizing & drying , filling & stoppering , укупорка:

adopts L shape in-wall structure, one-side operation,effectively realizes function division ,reduces cross contamination ,im proves aseptic security level . ORABS/CRABS,on-line IPC weighing system and filling CIP/ SIP can be equipped as option to realize isolation and automation of auxiliary operation.

District 6

Freeze dryer and auto loading & unloading system:

realize aseptic auto transferring from filling & stoppering machine to freeze dryer, freeze dryer to capping machine completely, reduce persons in asepsis room , reduce contamination risk , improve aseptic security level .

District 7

Укупорочная машина:

Provide machine model with differentfunction according to different cleanliness class; can realize aluminum particles auto collection , imaging testing before capping and other functions

District 8

Fully Automatic Inspection Machine:

adopts machine to substitute person , improves inspection efficiency and reliability, has small space and low running cost , can realize automatic inspection for visible particles,appearance defect and capping defect in freeze drying products .

District 9

Fully Automatic After-Packaging Compact Line:

adopts automatic packaging compact line of pallet making, pallet entering ,three-dimensional wrapping, packing , strapping, palletizing. This line can reduce labor intensity and production cost , improve production efficiency and packing quality rate .

District 10

Automated stereoscopic warehouse:

effectively connect production and store , auto storing and retrieving , improve labor productivity, reduce labor intensity, improve space utilization and goods management quality.

District 11

On line integration monitoring room:

realize production data collection of each system, person working state collection , informat ization of equipment operation & maintenance management , can communicate with global customers through remote service measuring and control center, realize preventive maintenance , remote video for trouble confirmation and maintenance guidance .

Производство и гарантия качества

Возможности обработки

|

|

|

|

|

обрабатывающий центр с ЧПУ |

Робот-автосварка |

Полировальная машина |

|

|

|

|

|

Сборочный цех |

Управление складом |

ТОП мастерская |

|

|

|

|

|

Бороскоп |

Детектор шероховатости поверхности |

Испытание материала |

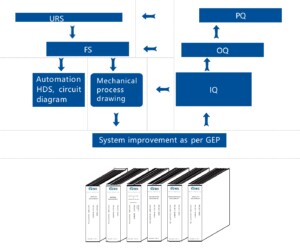

Валидация и документирование

|

В качестве критически важных инженерных сетей фармацевтических заводов, следуйте модели V от планирования до запуска. Documents meet validation requirement, автоматическое управление может соответствовать GAMP |

|

Сервисная поддержка

|

|

|

|

|

Богатый опыт управления проектами Сильная команда управления проектами, |

Общий дизайн решения в соответствии с требованиями пользователя |

|

|

|

|

|

|

Повторная оптимизация конструкции для продукта, требуемого заказчиком |

24 -консультационные услуги по часам |