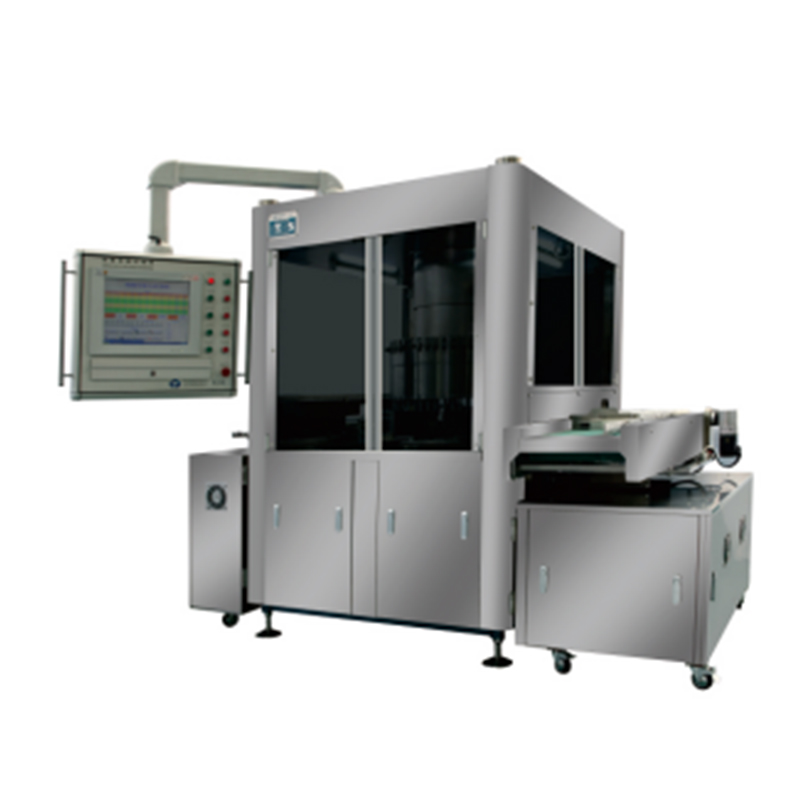

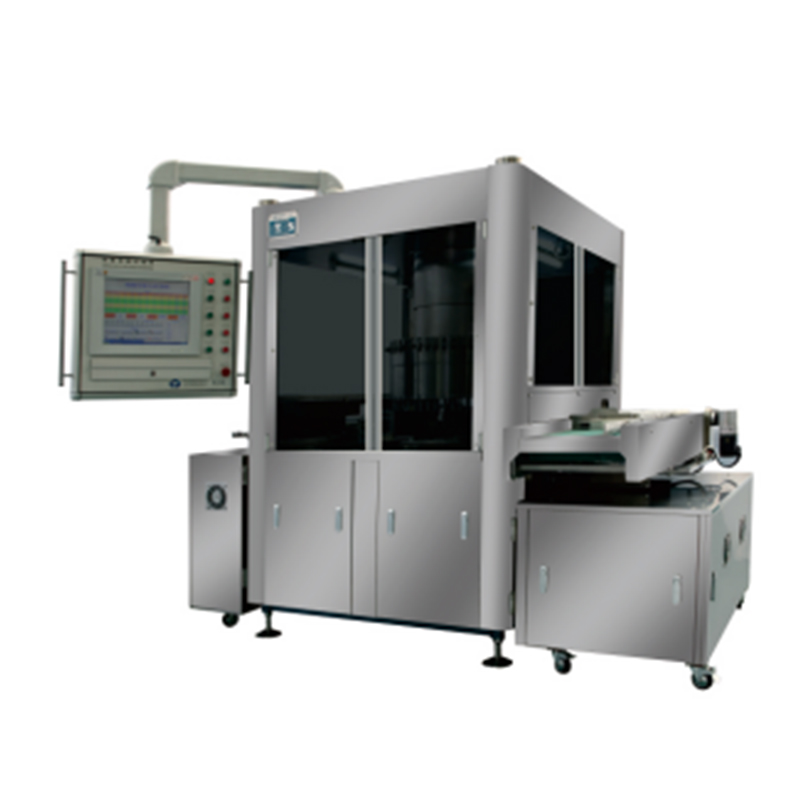

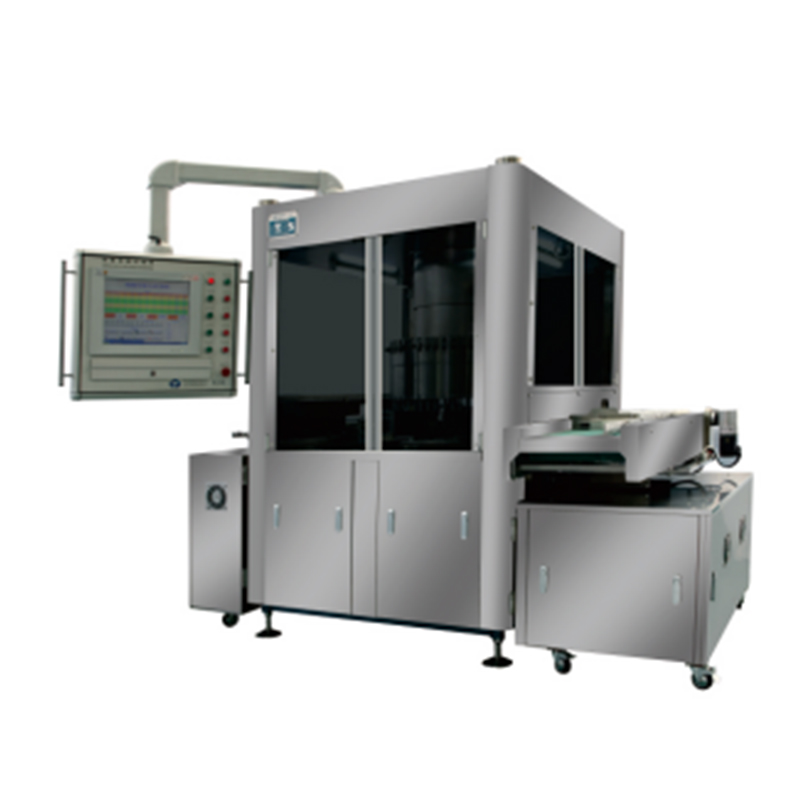

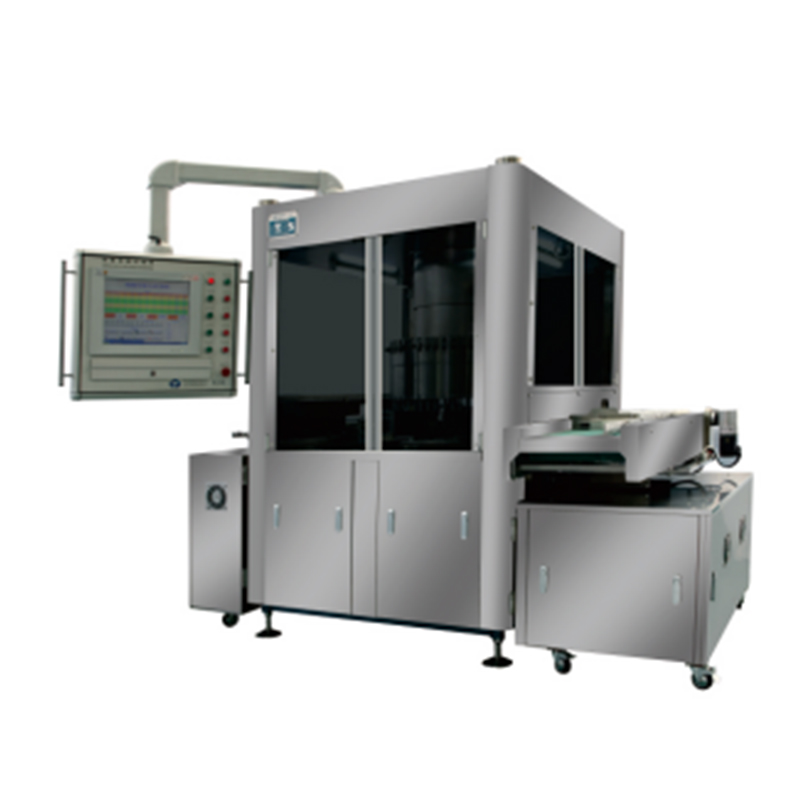

Categories: Production line pharmaceutical machines

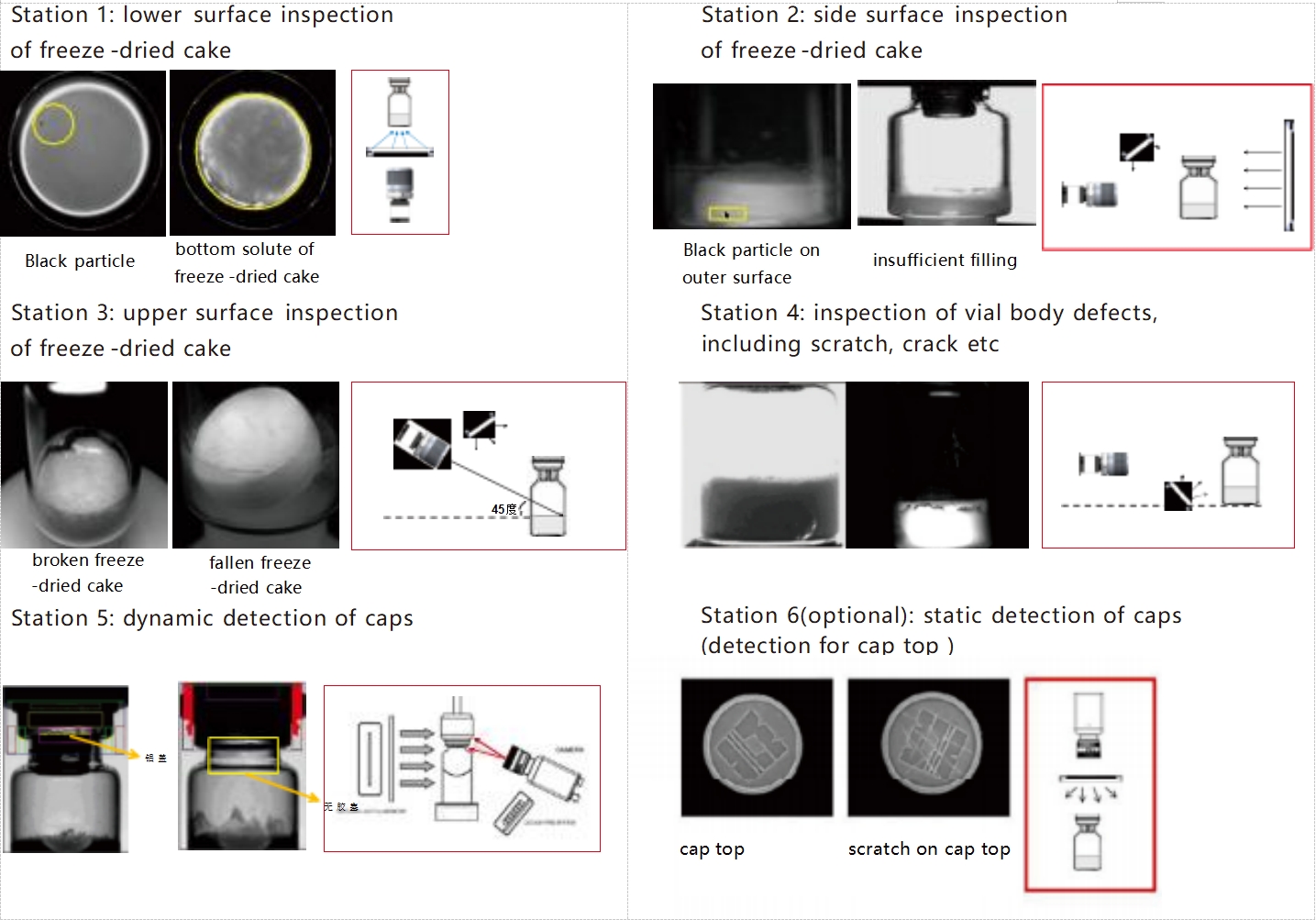

Mainly used for automatic inspection of visible particle, apparent defect and sealing defect for vial freeze drying products in pharmaceutical factory.

Product defect

Sealing defect

Vial body defect

Manufacturing and Quality Assurance

Processing capability

|

|

|

|

|

CNC machining center |

Robot auto welding |

Polishing machine |

|

|

|

|

|

Assembly workshop |

Warehouse management |

TOP workshop |

|

|

|

|

|

Boroscope |

Surface roughness detector |

Material test |

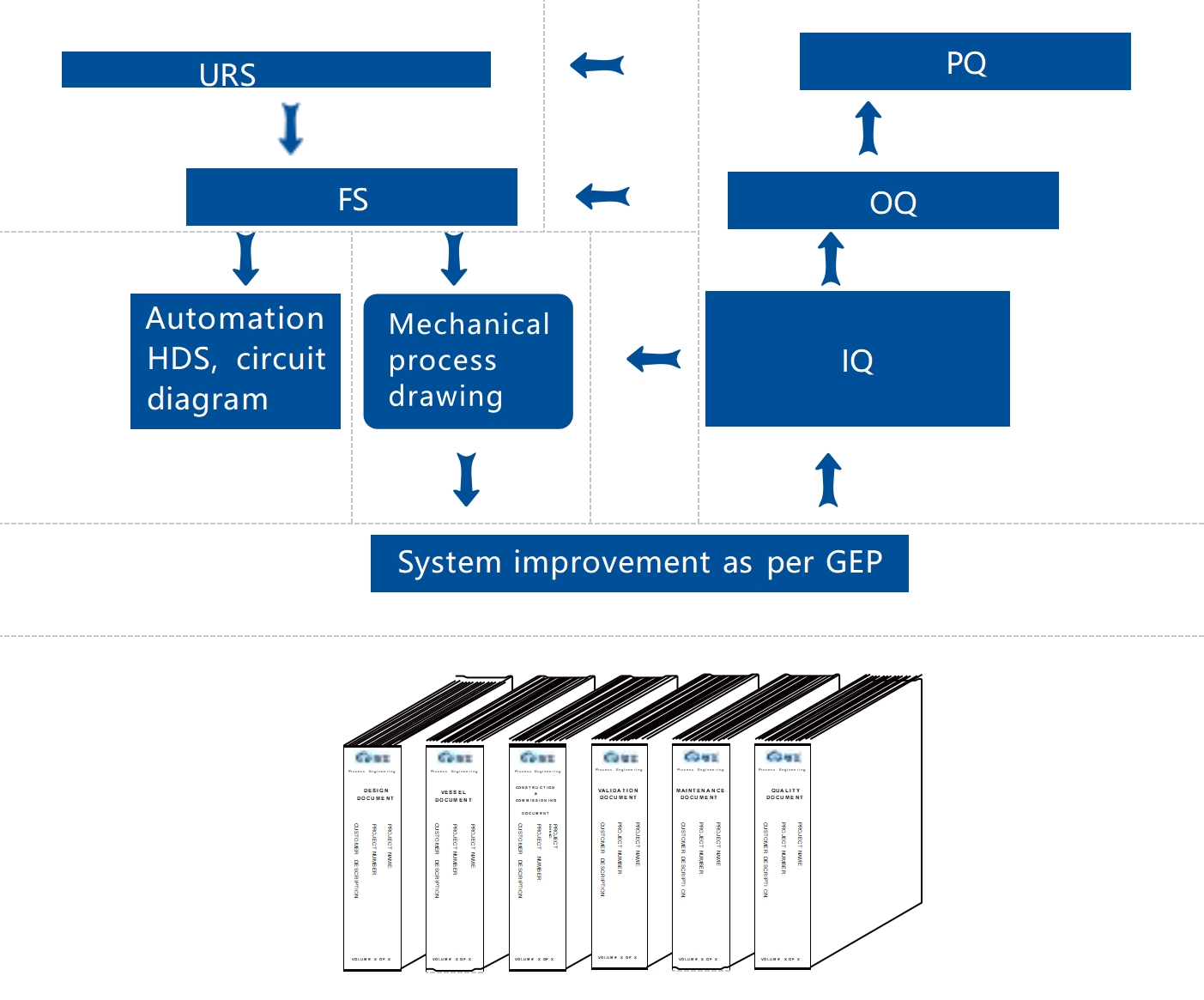

Validation and document

|

As Critical utilities of pharmaceutical factories, follow V model from planning to running. Documents meet validation |

|

Service support

|

|

|

|

|

Rich project management experience Strong project management team, |

Overall solution design as per user ’s requirement |

|

|

|

|

|

|

Re -optimization design adjustment for customer required product |

24 -hours consulting service |

PeptideGurus is a leading supplier of American-made research peptides, offering top-quality products at competitive prices. With a focus on excellence and customer service, they ensure a secure and convenient ordering process with global shipping.

CONTACT