In the rapidly evolving field of biotechnology, peptide synthesis has become a cornerstone of research and development. However, the debate between utilizing a small scale peptide production line versus in-house synthesis is ongoing. The advantages of small scale peptide production lines over in-house synthesis are numerous and compelling. These facilities offer specialized equipment that ensures high precision and quality, which is often difficult to achieve with in-house setups. Additionally, the expertise available at these production lines can significantly reduce the risk of errors and enhance the consistency of the peptides produced.

One of the primary advantages of small scale peptide production lines is the cost-effectiveness they offer. Setting up an in-house synthesis laboratory requires substantial investment in equipment, materials, and skilled personnel. In contrast, outsourcing to a dedicated production line can significantly reduce these costs. These facilities often operate at an economy of scale, allowing them to produce peptides more efficiently and at a lower cost per unit. This is particularly beneficial for startups and smaller research institutions that may not have the financial resources to invest in their own synthesis capabilities.

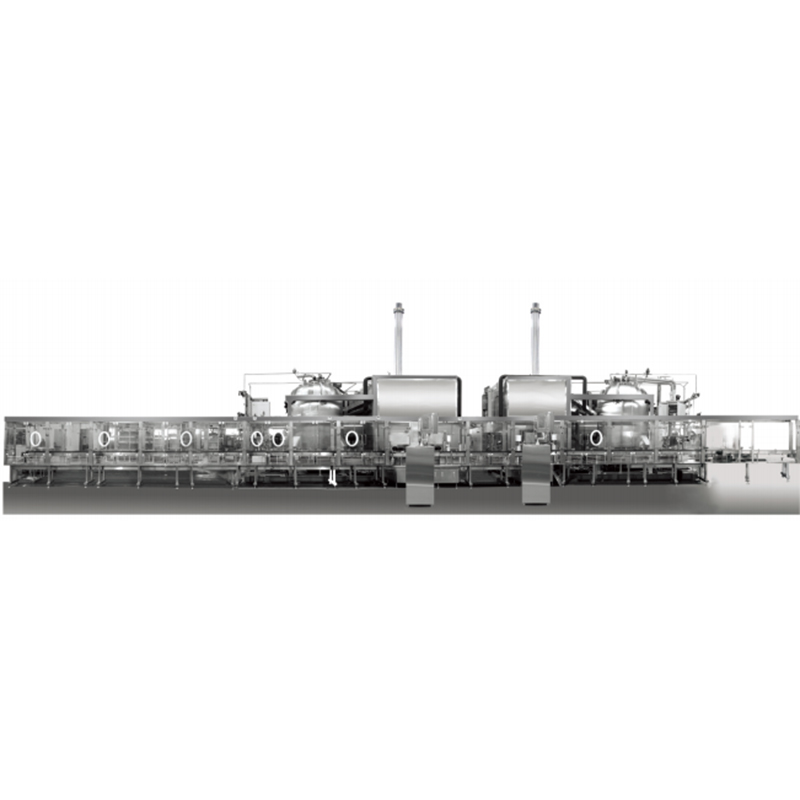

Furthermore, small scale peptide production lines offer unparalleled flexibility and scalability. In-house synthesis can be limited by the capacity of the equipment and the expertise of the staff. However, production lines are designed to handle varying scales of production, from small batches for research purposes to larger quantities for commercial applications. This scalability is crucial for adapting to the changing needs of research and development projects, allowing organizations to efficiently manage resources and timelines.

PeptideGurus is a leading supplier of American-made research peptides, offering top-quality products at competitive prices. With a focus on excellence and customer service, they ensure a secure and convenient ordering process with global shipping.

CONTACT