Categories: Production line pharmaceutical machines

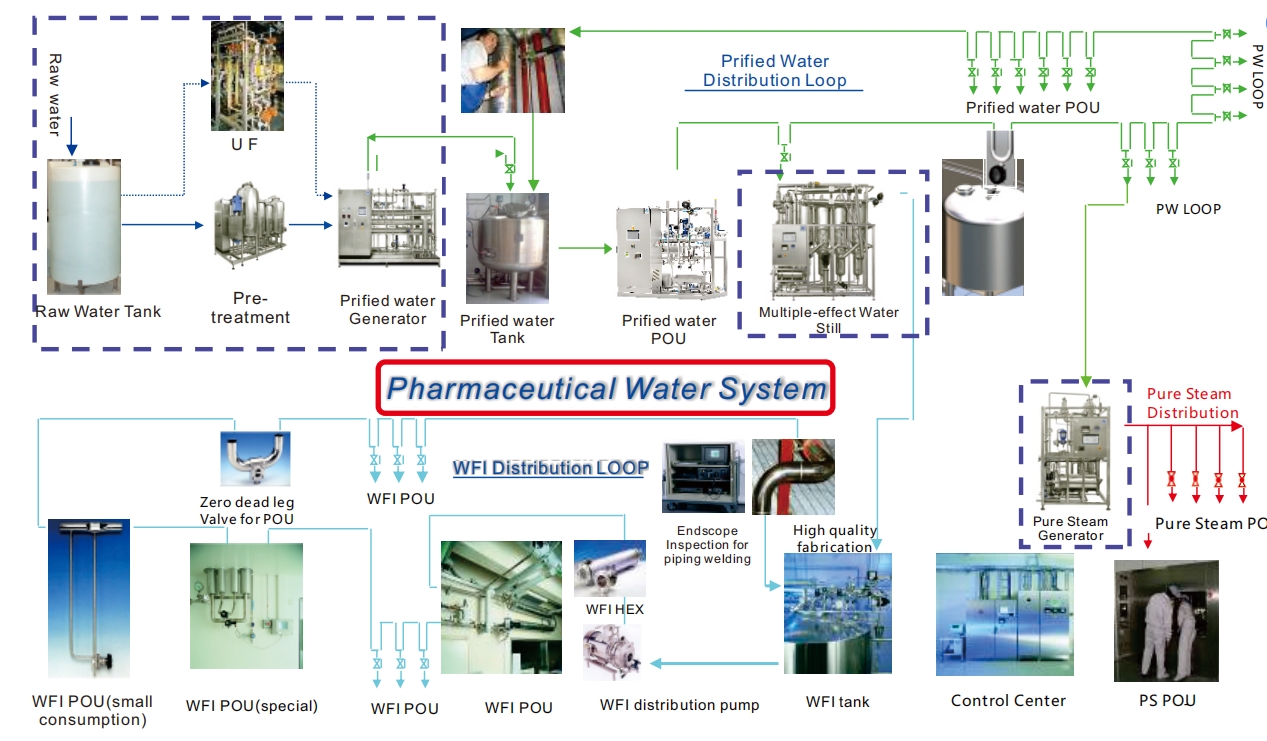

Purified Water

Generator equipment

WFI Generation device

Pure Stream Generator

Water Distribution System

Manufacturing and Quality Assurance

Processing capability

|

|

|

|

|

CNC machining center |

Robot auto welding |

Polishing machine |

|

|

|

|

|

Assembly workshop |

Warehouse management |

TOP workshop |

|

|

|

|

|

Boroscope |

Surface roughness detector |

Material test |

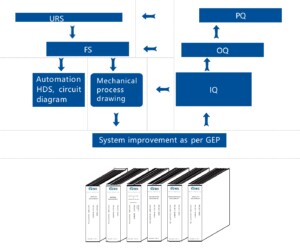

Validation and document

|

As Critical utilities of pharmaceutical factories, follow V model from planning to running. Documents meet validation |

|

Service support

|

|

|

|

|

Rich project management experience Strong project management team, |

Overall solution design as per user ’s requirement |

|

|

|

|

|

|

Re -optimization design adjustment for customer required product |

24 -hours consulting service |

PeptideGurus is a leading supplier of American-made research peptides, offering top-quality products at competitive prices. With a focus on excellence and customer service, they ensure a secure and convenient ordering process with global shipping.

CONTACT